- Home

- Electric Utility

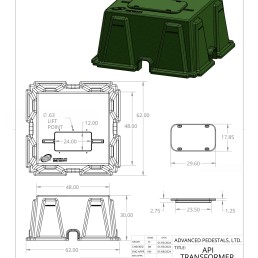

- Transformer Pad

Reliable Transformer Pads for Utilities

Designed by a Lineman For Linemen

Customizable Transformer Pad

With the backlog of transformers reaching up to 2 years, electric utilities are forced to get creative while they wait. A common solution is to mount the units on the supply pole in the interim, which requires additional processes to rework for underground applications once the transformer arrives. This results in service interruptions, which can pose a significant inconvenience for residents and businesses alike.

API’s specially designed transformer box pads are a cost-effective alternative that saves time and labor by protecting the underground components while allowing easy access to complete maintenance and to install the delayed transformer. This can significantly reduce construction costs and project delays.

API’s Transformer Pad is designed to provide secure protection while waiting for single-phase pad-mounted transformers from 25 kVA to 167 kVA. Constructed from non-corrosive and non-conductive durable materials that are lighter than concrete and more durable than fiberglass, these pads are a versatile solution to enhancing protection and security against weather and intruders.

The Transformer Pad includes a removable lid, allowing the pad to be set and construction to continue while waiting on transformer delivery, saving time and reducing disruption of electrical service.

- The UV-resistant material is available in both industry standard and custom colors, allowing for customization to fit aesthetics and company branding.

- Tamper-resistant penta-head bolts secure the lid, preventing ingress and protecting the vital electrical components within.

- Specially designed to accept select sectionalized cabinets with strategically placed cable entry and exit points and equipment mounting capabilities.

API uses the latest rotational molding technology and prime melt compounded polyethylene to construct durable solutions for transformer box pads. API’s transformer pads are built to ensure in-ground stability as well as a stable foundation. The seamless, double-wall design features increased material thicknesses in high-stress areas, making them impact-resistant and eliminates cracking.